Skate bearings are an often overlooked component of any skateboard or longboard. After all, skate bearings are simple. They’re little more than a couple of hardened steel (or ceramic) balls resting between two rings (called races), packed with some grease… right?

While the above is true — bearings are mechanically simple — there are some key aspects about bearings that can influence how your wheels roll and, by extension, how well (or poorly) your board rides.

Skate Bearings: Common Questions

Pictured: Bones Red bearings (8-Pack)

There are also plenty of common questions when it comes to skate bearings. Let’s answer those first, then get into the specifications you should look for when buying a set.

Are skate bearings universal?

A: When it comes to compatibility, yes. There’s just one bearing size that works with all skateboard and longboard wheels and trucks:

- 8mm inner diameter

- 2mm outer diameter

- 7mm width

What Makes Up a Skate Bearing?

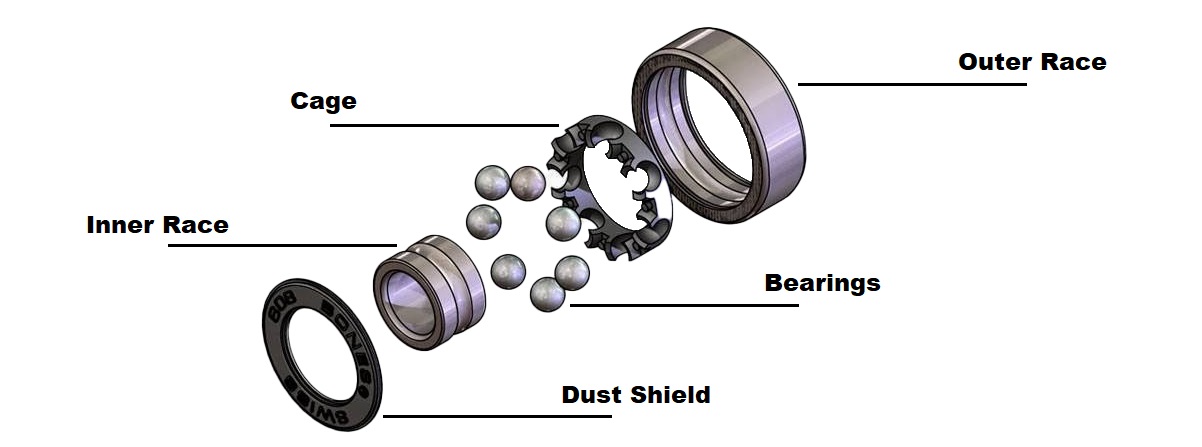

A: There are five key parts to any skate bearing, as exampled by the diagram of the Bones Swiss Bearing above:

- Outer Race: This outer steel ring holds the bearing’s components together. Press-fits inside the wheel, holding the bearing inside place.

- Cage: Also called a retainer. This assembly keeps the bearings centered inside the races.

- Bearing Balls: The actual bearings inside the assembly. Skate bearings have 7 balls.

- Inner Race: Sandwiches the bearings and cage inside the outer race, and slides over the truck axle shaft.

- Dust Shield: Prevents debris from getting inside the bearing, causing damage. Also keeps grease from escaping. May be press-fit, or may be held inside the races with a C-ring.

What’s an ABEC bearing?

A: ABEC refers to the Annular Bearing Engineering Committee, the organization that created the ABEC Rating standard used to grade the quality of skate bearings (and other bearings used in different industries).

The ABEC Rating uses odd numbers (1, 3, 5, 7, 9) to grade a bearing. The higher the number, the tighter the bearing’s tolerances. Tighter tolerances mean a bearing can perform better, spinning faster with less resistance, and wearing more slowly.

What ABEC Rating should I pick for skate bearings?

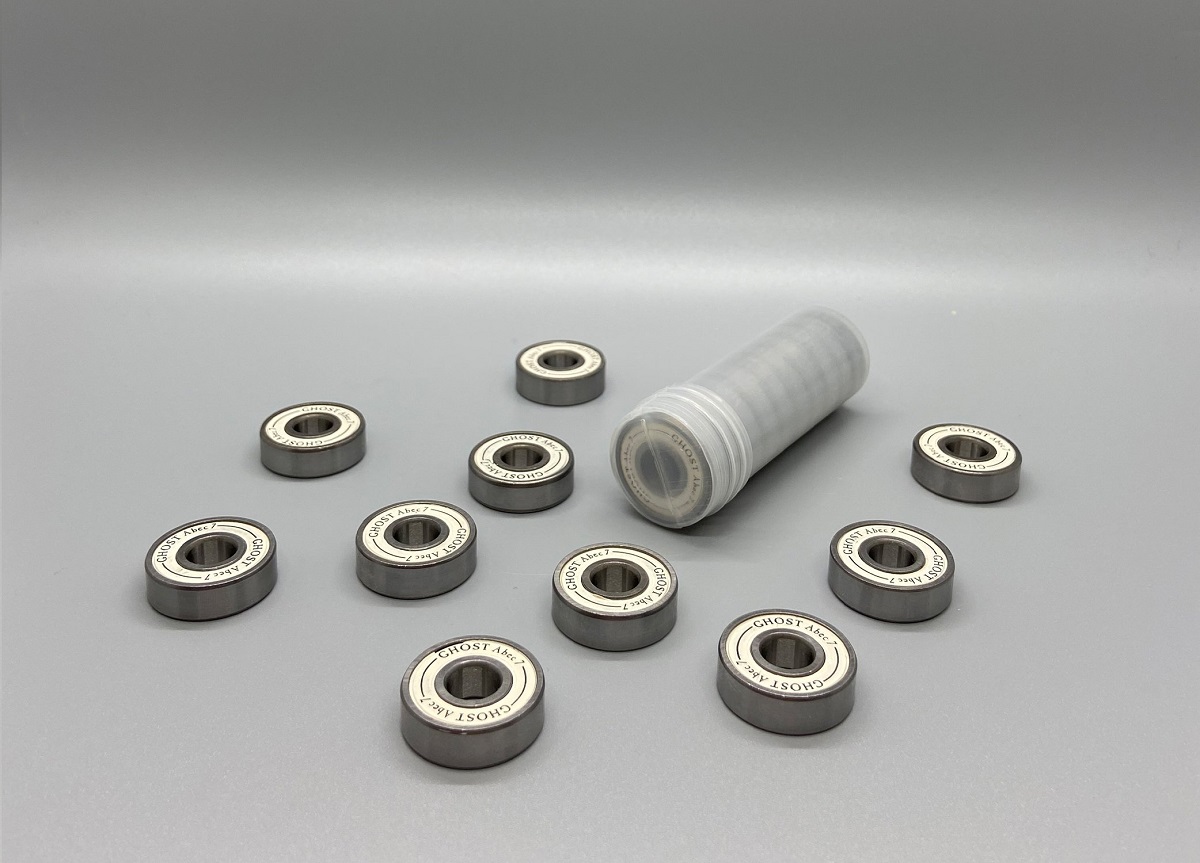

Pictured: Ghost ABEC 7 Bearings

A: Most skaters prefer bearings with an ABEC Rating of 7 or 9. These ratings balance performance and longevity with cost.

Bearings rated between 1 and 5 are generally OK — but they have looser tolerances, may wear more quickly, and typically perform poorly at high speeds.

What’s the difference between ABEC and Skate-Rated bearings?

A: Bones Bearings ditch the ABEC Rating standard for their own set of standards. This is because ABEC Ratings only measure a bearing’s tolerance for the purpose of spinning at certain speeds.

Skate bearings also deal with side-loading and hard impacts — something the ABEC Rating system doesn’t account for when grading a bearing’s performance.

Skate-Rated bearings are redesigned to better withstand impacts and hard landings, and side loading — such as when you’re carving tightly on a skateboard, or sliding on a longboard — without suffering premature wear or damage.

What’s the best overall skate bearing?

Pictured: Bones Swiss Bearings (8-Pack)

A: Bones Bearings are considered to be the top option on the market, with Swiss Bearings being the company’s best, highest-quality set. They’re used by all the pros, and their Skate-Rated design ensures your bearings don’t lose their dust shields, crack any balls, or pop a race off the cage when riding hard.

Are ABEC bearings good enough for skating?

A: Of course! Although “Skate-Rated” bearings are considered top-of-the-line, a quality ABEC 7 or ABEC 9 bearing will last through hundreds (if not thousands) of hours’ worth of hard skating. They’ve been in use for decades, and continue to be favored by most skaters.

Skate Bearing Materials Compared

Bearings are simple in construction, but the alloys and materials used to make them play a huge role in their performance.

Steel Bearings

Pictured: Rush ABEC 7 Steel Bearings

Steel bearings remain the gold standard in skating, and they’re by far the most popular. Quality steel bearings use a type of steel called AISI 51200. This is a high carbon-chromium alloy. The high chromium content of the alloy increases surface hardness, which reduces friction and wear. It also promotes rust protection.

Ceramic Bearings

Pictured: Bones Ceramic Super Reds Bearings

Ceramic bearings use ceramic balls inside their races. These bearings’ races are made of steel, like typical bearings. Ceramic bearings are roughly 30% harder than steel bearings, and they resist rust, so they wear more slowly. Ceramics also use smaller balls, and more of them, inside the races. Some skaters claim this provides a smoother ride quality.

Extra smoothness and a longer lifespan are the only two benefits of running ceramic bearings in your longboard or skate wheels.

Contrary to popular belief, ceramic bearings do not provide a meaningful increase in speed, nor any real reduction in friction. That’s because most of the friction a bearing experiences is caused by the grease inside the races, and the dust shield protecting the bearing from contamination.

Bearing Spacers

Bearing spacers are the small cylindrical tubes that rest between each wheel’s inner and outer bearing on the truck’s axle shaft. The spacer helps ensure the weight placed on the wheel hub is evenly distributed between both bearings.

Spacers also prevent your bearings from unseating or rotating inside the wheel hub when you’re pushing your board hard — this is more likely to occur if you’re sliding on a longboard, which exerts high side loads on the wheels.

Are spacers required?

No. You’ll rarely, if ever, find bearings spacers on standard skate wheels. It is recommended you run them on longboards, though. The typical longboard’s wider wheel hub (and the greater side loads frequently experienced when carving and sliding) can result in more rapid bearing wear, and deformation of the bearing races, if spacers are not used.

Speed Rings

Speed rings (also called speed washers, or bearing washers) are the small washers that rest on either side of wheel assembly. One washer is placed between the inner bearing’s outer face and the end of the axle shaft — where it terminates into the truck hanger — while the other rests between the outer bearing’s outer face and the axle nut.

These speed washers spin freely when the wheels rotate, reducing friction that the bearings races would otherwise experience by making direct contact with the axle nut and hanger.

Are speed rings required?

No, but we strongly recommend you always run them. Without washers, your bearing races will rub against your truck’s hangers and axle nuts, wearing them down prematurely. You may also find that, without washers installed, your wheels feel gritty when rolling; they may not spin as freely.