How to choose Longboard Wheels, simple steps on finding the write size for you.

You’ve started picking your longboard parts to build a custom board. You’ve figured out what trucks to get, you’ve got a deck shape picked, and now you need one of the most important pieces: The wheels you’ll roll on.

Longboard wheels — and skate wheels, for that matter — are, not surprisingly, a complicated topic. You’ve got to consider a bunch of specs, like wheel diameter, hardness, width, and wheel shape, and smaller things, like the wheel’s edge and core.

Confusing? Let’s break it all down. Here’s how to pick longboard wheels, by the facts and figures.

Longboard Wheel Size: What’s Best How to choose Longboard Wheels?

Longboard wheels come in all kinds of sizes. Their diameters are measured in millimeters. The higher the number, the bigger the wheel. Here are the basic rules to know:

- Bigger wheels can provide a higher top speed, but they accelerate more slowly.

- Bigger wheels have a greater contact patch, providing more grip and stability.

- Smaller wheels accelerate more quickly, but their overall speed is limited.

- Smaller wheels have a lesser contact patch, making them more responsive.

To summarize it simply: Big wheels have higher top speed, and small wheels accelerate quicker.

(Terrain Determines Wheel Size, Too)

Longboards are designed to ride far and wide — and that means dealing with plenty of different terrains and surfaces. You might enjoy smooth concrete sidewalks and bike lanes in your area, or you may deal with rough roads covered in gravel and debris.

Bigger wheels fair better on rough terrain. Small wheels can get locked up when they roll over even small pebbles — which can result in your board suddenly going 0 MPH while you continue onward, flying forward face-first.

Wheel Diameter vs. Riding Style

Picking the right longboard wheel diameter ultimately depends on your riding style. Keep in mind that while all longboard wheel sizes fall in a tight range (about 65 to 100mm) just a few millimeters’ change in diameter can make a big difference in handling and performance. Let’s compare:

65mm – 72mm: For Free Riding, Sliding, Commuting/Cruising

65 to 72mm longboard wheels fall in the “Goldilocks” zone. They generally do everything great: They afford predictable, easily controlled slides. They’re capable of managing rough roads and crumbly sidewalks. They balance acceleration and top speed.

They do great in high-speed, downhill runs without sacrificing acceleration and braking in crowded areas. They also provide good responsiveness when riding slalom.

Most standard longboards use 70 or 72mm wheels. These boards’ decks usually measure 36″, 40“, or 48″. Smaller decks (24″ to 30″), designed for tight spaces and crowded streets, also do well with 65mm to 70mm wheels.

70mm – 80mm: For Downhill Runs, High-Speed Riding

Wheels on the upper end of this diameter range focus on top speed. Downhill riding naturally provides plenty of acceleration, so this isn’t a concern for wheels of this size. The logic here is simple: The faster you want to go, the bigger the wheel you want.

You’ll also want to stick with a larger wheel — closer to 80mm — if the hills you’re bombing tend to have poorer quality pavement, more debris, and tighter turns.

80mm – 100mm: For All-Terrain Riding, Exploration

Speaking of debris: You’ll need even bigger wheels to handle all-terrain situations. If you find yourself exploring craggly backcountry roads, potholed bike paths in the woods, or if you just want the assurance that your longboard can handle the miles of unknown blacktop ahead, an 80 to 100mm wheel is ideal.

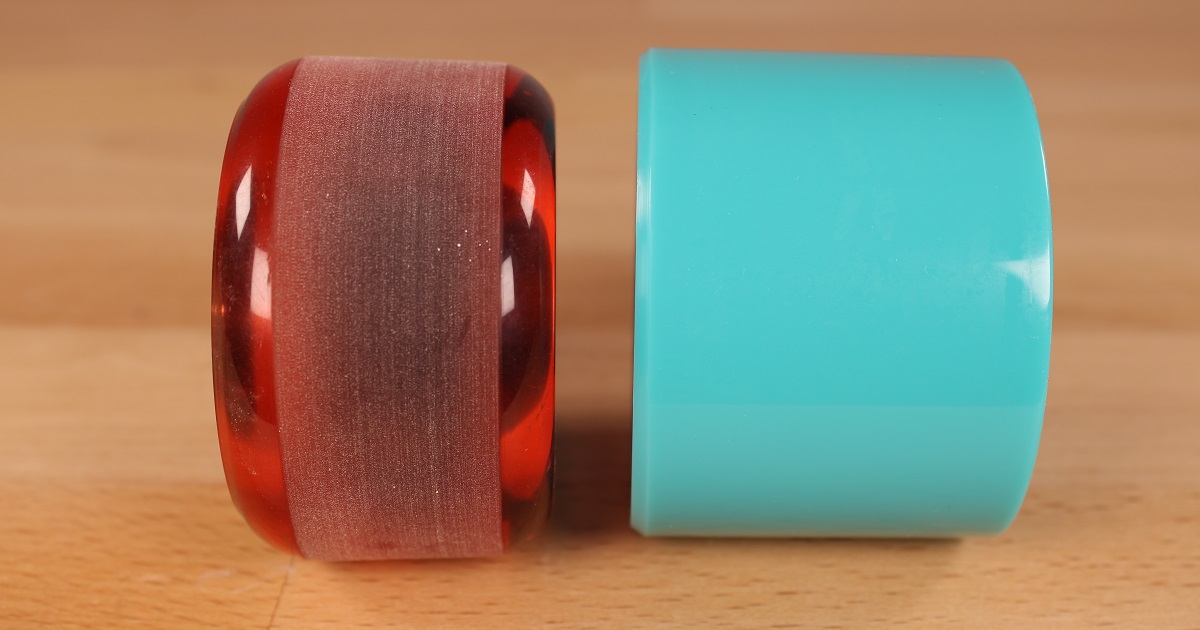

Wheel Width & Contact Patch

longboard wheel width is no different in concept than the width of your car’s tires: The wider the wheel, the bigger the contact patch, and the greater the grip.

Wider wheels also produce a less progressive slide — in other words, they’ll break grip more suddenly once you push your board past the limits of your wheels’ grip, affording an overall less predictable slide.

This is why the widest possible wheel is almost never the best, for any diameter.

If you find your wheel diameter provides good speed and acceleration but produces sudden, unpredictable, and jittery slides when you’re pushing the limits of grip and making tight turns, consider looking for a narrower wheel.

Wheel Hardness

Longboard wheel hardness plays a key role in determining grip (and, therefor, carving and sliding ability), and how the wheel handles rolling over debris and rough terrain. Wheel hardness is measured on the Durometer Shore A Scale, which rates the hardness of wheel urethane. This scale ranges from 0 to 100, but most longboard wheels measure between 75a and 100a hardness.

75a – 78a: Best for High Grip, Cruising, Carving

Most standard longboard wheels come with a 78a hardness. This wheel hardness favors grip and high responsiveness, allowing for tight carving with little sliding. This hardness rating is best for beginner riders, and those who cruise casually, or commute with their boards. You’ll also want a 78a hardness for handling rough terrain.

80a – 87a: Best for Free Riding, Learning to Slide

Wheels in this hardness range provide more capability when learning to slide. These wheels can slide predictably, with moderate deceleration throughout the slide. This helps to prevent overshooting and wiping out. These wheels still perform well on most terrain, albeit with less damping and more shock/rebound when striking pebbles and gravel.

90a – 100a: Best for Advanced Sliding, Tricks

Wheels within this hardness range slide with incredible ease — but they sacrifice grip and generally ride harsh on any surface that isn’t smooth and flat. Most riders who roll on wheels this hard are focused on performing tricks, like 180- and 360-degree spins, and leaving long “‘thane tracks” (the longboarding equivalent of leaving skid marks from a burnout).

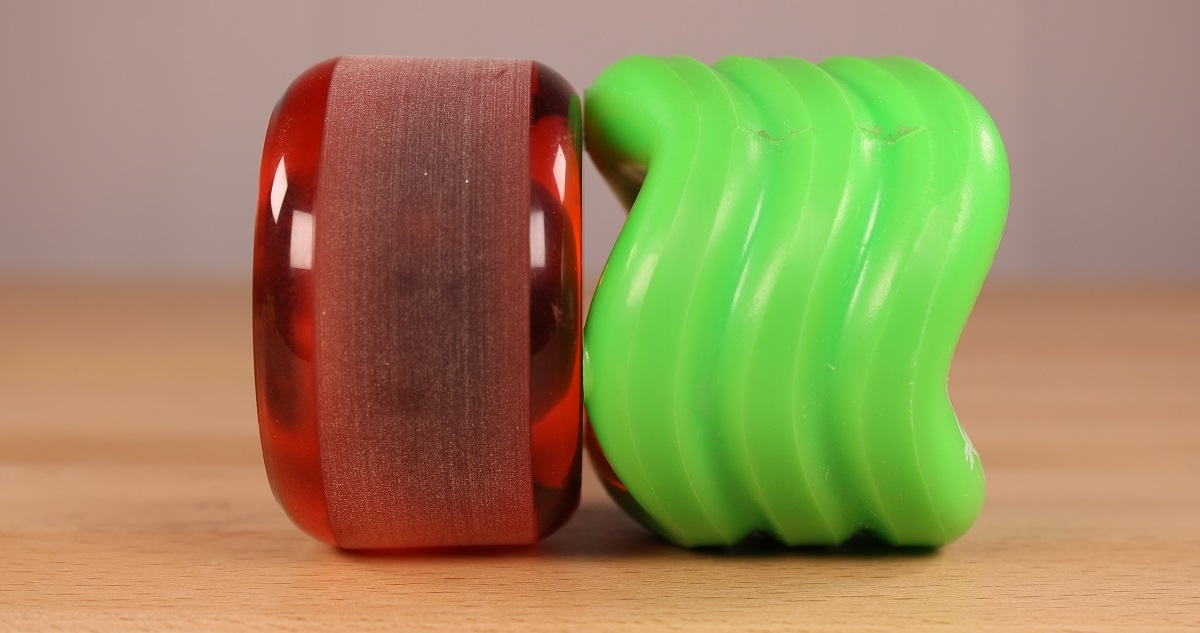

Wheel Lip / Edge

Longboard wheels are poured and molded with different lips, or edges. This is where the contact patch transitions to the wheel’s side wall. The lip of the wheel plays a lesser, but notable, role in handling. Here’s the basic breakdown:

- Wheels with sharp edges provide the most grip

- Sharp edges bite the pavement in slides, reducing speed

- Rounded and beveled edges provide more predictable slides

- Rounded and beveled edges also slide longer, with less deceleration

Let’s look at different wheel edges a bit more.

Square Edge

Most longboard wheels have square edges. Square wheel edges promote the most control. Square-edged wheels can slide, but they’re not ideal for extensive sliding: They tend to break more suddenly than other edge profiles (also called an non-progressive slide action), and they decelerate quickly when sliding.

If you’re practicing sliding on wheels with square edges, you’ll notice that, over time, the edge will self-radius: It’ll round out, reducing the contact patch width and allowing for greater slide speed and length over time.

Beveled Edge

Beveled edges balance grip and slide capability. With a narrower contact patch and angled drop-off between the contact patch and side wall, beveled wheels provide less resistance when sliding, with a more progressive slide action. They’re great for beginners who want to learn to slide, as they offer good predictability and deceleration.

Rounded/Radius Edge

Rounded edges are best for longboard riders who prefer sliding frequently, and who don’t mind rolling on a wheel with lower overall grip. These wheels slide very smoothly and predictably, with the most progressive action.

Rounded edges with a bigger radius will produce more progressive sliding, with less grip, while a smaller radius promotes more grip with a less progressive action.

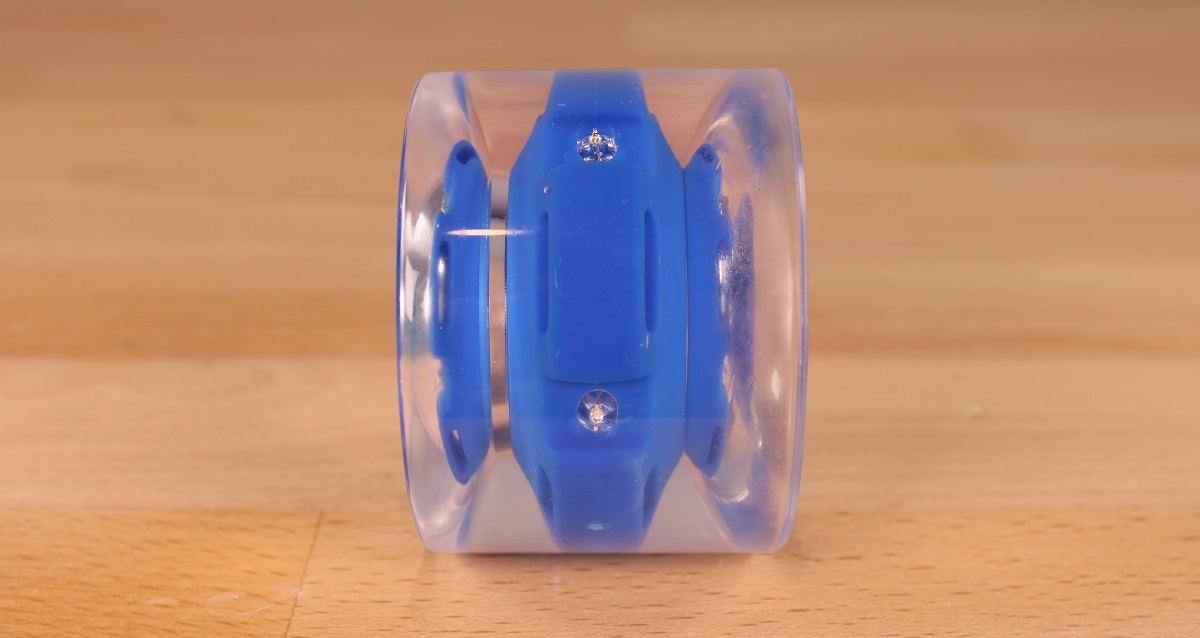

Wheel Core Size & Placement

The core of the wheel holds the wheel’s urethane, bonding it to the hub that contains the wheel’s bearings. The size and placement of the core, relative to its width, influences grip, wheel lifespan, and sliding potential.

Center-Set Cores Have The Best Lifespan

Center-set wheels have a core that rests in the center of the urethane. This allows the wheel to be flipped, and this configuration evenly spreads the load between the wheel and pavement across the entire contact patch.

Center-set wheels also balance grip and slide capability, making this core configuration a good “all-rounder” setup for different riding styles.

Back-Set Cores Favor Sliding the Most

A back-set core sits flush with the inner most edge of the wheel. This allows the urethane to slide easily, with high progressive action. This occurs because the inside edge of the contact patch — where most of the wheel’s grip is focused in turns — is highly supported, with little flex.

Offset Cores Provide High Grip

Offset wheel cores sit toward the inside edge, but not flush with the inner edge. This balances high support of the inside portion of the wheel’s urethane while still allowing for some flex, which promotes high grip. This setup is ideal for slalom riding, tight carving, and high-speed downhill riding.

Large vs. Small Cores

Large cores provide high support for the wheel’s urethane. This produces a more predictable ride, while also affording easy transitions from carving to sliding. The downside of a large core is that this results in less overall grip, with a harsher ride.

Small cores allows for more urethane to be added to the wheel, with more flex. This produces more grip, and a smoother ride. The downside is that sliding is less predictable and progressive, and softer urethane can wear unevenly over time.

Finally, You Can Pick Some Wheels!

With all your new-found knowledge, you can pick the perfect pair of longboard wheels to enhance your ride style and performance.

Read these guides to set up a truly dialed in board configuration: